We Are Linmore Video

Check out our new clean room with a printed circuit board assembly line.

BMW Irvine

CASE STUDY

In this video case study, BMW Irvine car dealership saves 90% energy in outdoor lighting by installing Linmore LED fixtures and UltraLink wireless lighting controls with Silvair technology.

Mercedes-Benz of Nashville

CASE STUDY

In this video case study, Mercedes-Benz of Nashville replaced 400W Metal Halide fixtures with 200W SL1 Site Area Lighters. The before and after is like night and day; much brighter, customer friendly, and safer with half the wattage consumption.

North Bakersfield Toyota

CASE STUDY

In this video case study, the North Bakersfield Toyota car dealership upgrades its indoor and outdoor lighting with Linmore LED light fixtures and UltraLink wireless controls with Silvair technology.

TRENDING PRODUCTS

Ace LED Area Light

(AA1)

Ace LED Garage

(AG1)

Ace LED Canopy

(AC2)

Ace LED Wall Pack

(AW2)

Ace LED High Bay

(AH1)

Linear 3.0

(LR3)

Site Lighter

(SL1)

Commercial High Bay

(CH2)

Essentials Series

(ES4)

Ace LED Door Kit

(AD1)

Hosedown 2.0

(HD2)

Ace LED Panel

(AP1)

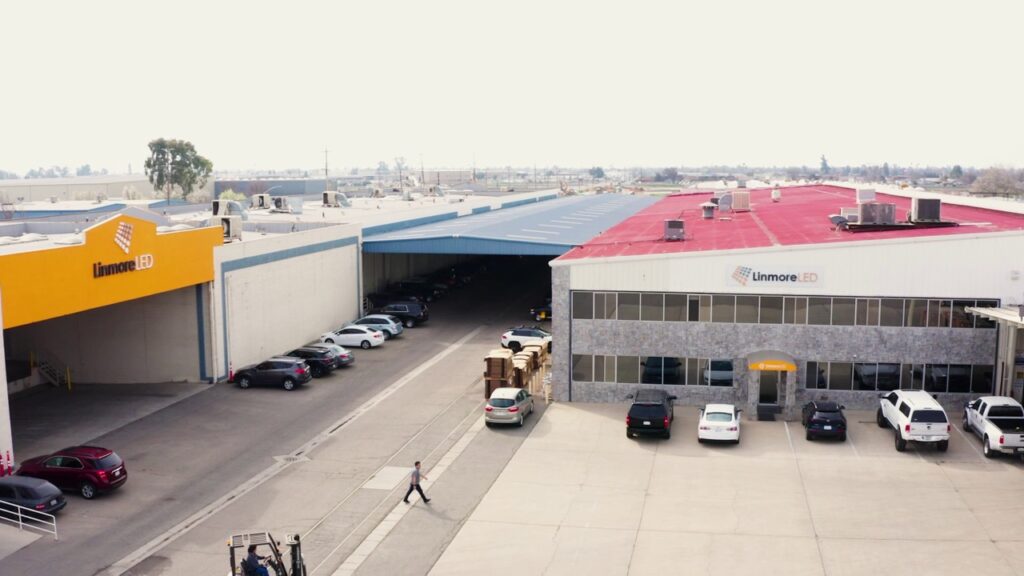

WHAT WE DO

We make exceptional LED lighting products for a wide range of applications and customer types

Linmore LED manufactures a broad portfolio of lighting solutions for most applications, from ultra-performance LED fixtures with integrated wireless controls, to high-value LED products and retrofit kits.

We Design and Manufacture the Highest Performing LED Product Line in the World

Our Brands

Industries Served

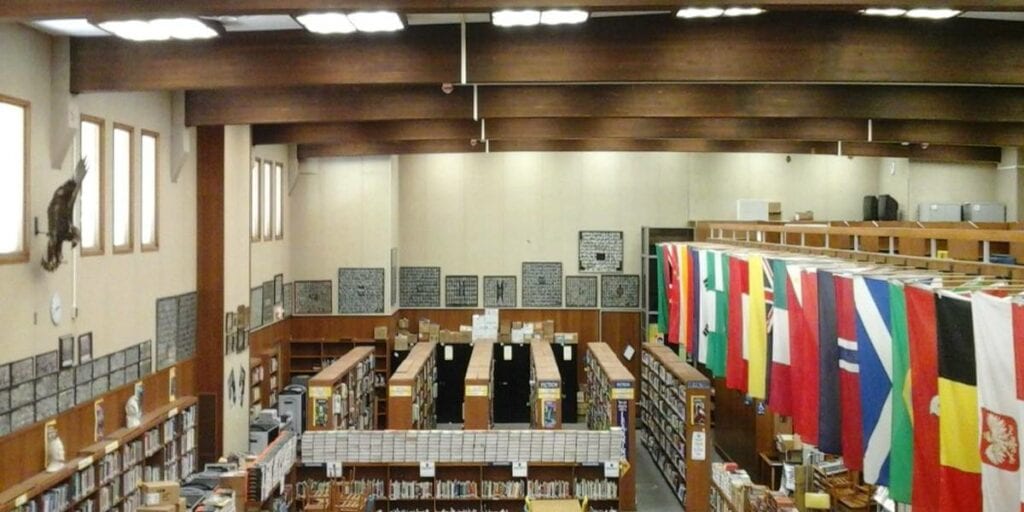

Warehouse Lighting

Safer and More Productive Warehouses

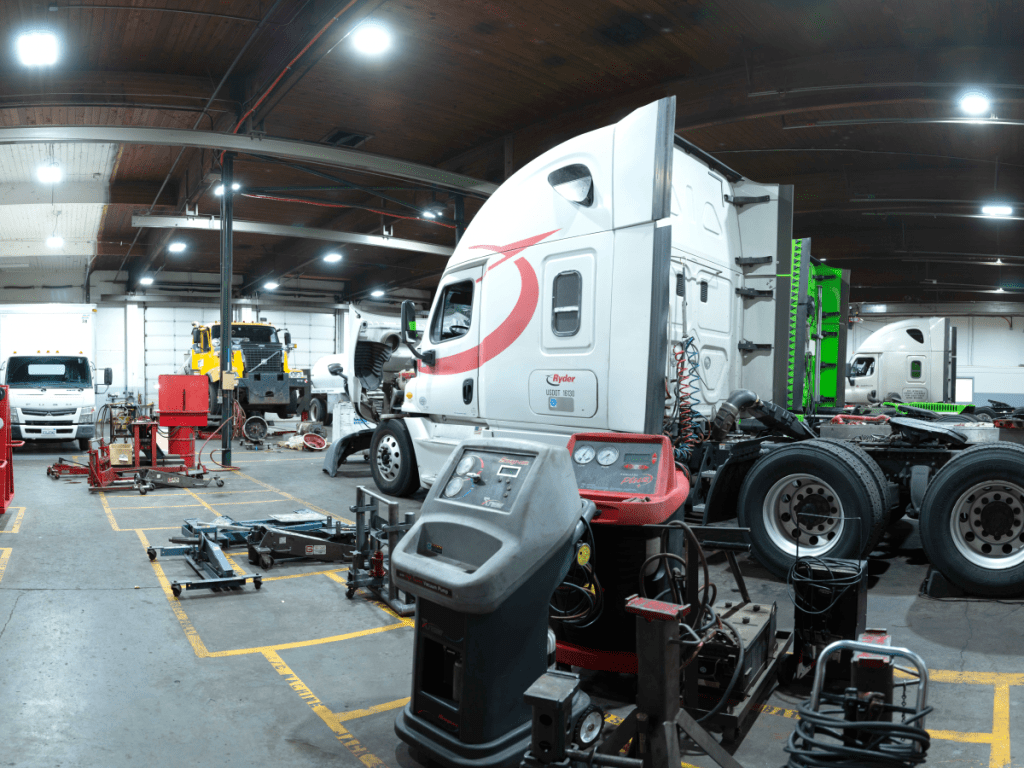

Industrial Lighting

Safer and More Productive Industrial Facilities

Food Processing Lighting

Safety, productivity, and cleanliness are critical to the

Indoor Sports Lighting

LED Lighting for Indoor Sport Facilities

Outdoor Lighting

Outdoor lighting solutions

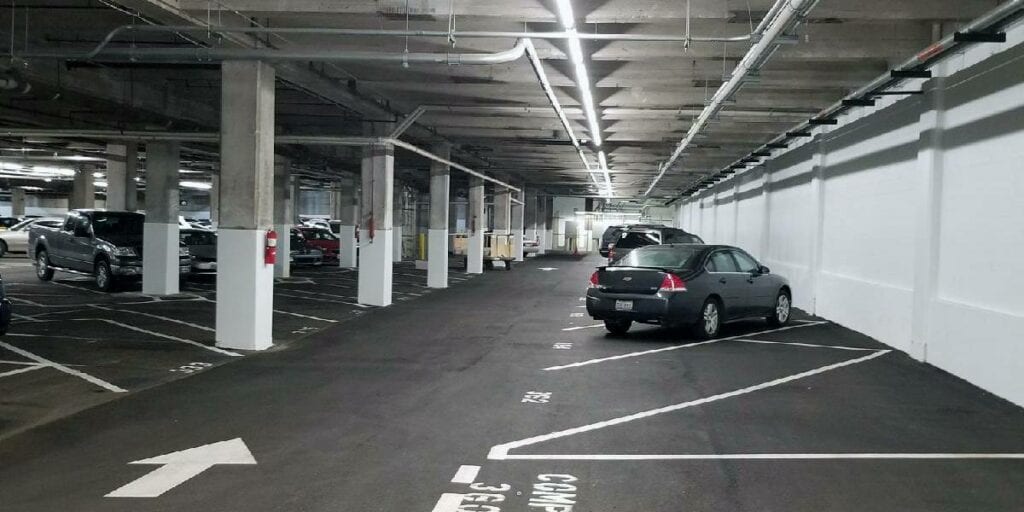

Parking Garage Lighting

Safer and Energy Efficient Parking Garages

Lumens as a Subscription®

Our LaaS program allows facilities upgrade to LED lighting without upfront costs.

The subscription includes a new lumen supply system, installation, and maintenance for 10 years.

The subscription includes a new lumen supply system, installation, and maintenance for 10 years.

GENERATE POSITIVE CASH FLOW WITH AN UPGRADE TO LED TODAY!

Our Customers

We Are as Good as What Our Customers Say About Us

Tom Emerzian

Owner, Emerzian Woodworking

I installed Linmore LED high bays, office lighting, and a parking lot lighting about a year ago under the LaaS program. We had lots of shadows from exhaust ductwork that the new lighting really improved. My guys in the shop love it. I think my savings are greater than projected.

Ligon de Vogel

VP Operations & Corporate Strategy

We opted for the LaaS program at the time because it was a great way to do a new system without making it a cap ex project, rather an operating expense. This has been easy to work with also from our accounting departments standpoint.

Steve Valencia

Owner of Waveform Electric Solutions

What I appreciate as a contractor is the ease of installation with the Site Lighter Rapid Mount Bracket, and I think Linmore really takes into consideration the contractor when they design the product. It makes our job easier; we can do it faster and more efficient.

Lee Crecelius

VP of Shelly Automotive Group

With Linmore LED making products in the US, we love that our LED lighting will be well supported. After completing two projects and seeing 85-90% energy savings, Linmore LED is now our only lighting partner going forward.

Andy Pappas

GM of North Bakersfield Toyota

The time and attention they put into their product, you can see it, you can feel it, you can hear it in their voice when they’re talking to you about their product.

Wade Newton

Owner, Energy Management Solutions Inc.

I really appreciate every single one of you for the help I receive when needed. That is why I am selling the product, it's not the company, it's the people who make the company great!

Case Studies

Light ‘Em Up Sales Contest

Earn your chance to win a brand new Corvette!

Sales reps from agents, distributors, ESCOs, and contractors that specify any Linmore LED or Ace LED products.

The contest period is from January 1, 2024 to December 31, 2025.

What's New?

Receive Updates from Linmore LED

Headquarters

2360 S Orange Ave

Fresno, CA 93725

Fresno, CA 93725

Design Center & Innovation Hub

710 Century Pkwy

Allen, TX 75013

Allen, TX 75013